K-Lab develops and manufactures innovative, high quality laser scanning systems in combination with unique vision solutions for a wide range of industrial applications. The K-Lab laser solutions are products of extensive experience and strong know-how that K-Lab´s professional team has developed over the years. The main fields of industrial applications are micro-machining, high performance remote welding, remote cutting and additive processes. Therefore K-Lab is offering standard and also customized solutions. The company stands for continuously further developments and is dedicated to evolving their knowledge and experience in order to deliver innovative products and expertise, which advances customer´s technologies. The worldwide customers base of K-Lab´s starts from well-respected institutes up to OEM-customers of high technology industries.

Scout

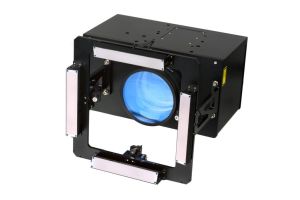

The SCOUT scan head laser system is a unique marriage of laser processing guided by an ultra-precise machine vision technology. It offers laser scanning solutions with a monopoly position in the current scan head industry. It has been appreciated by industrial customers around the world for its quality, precision, reliability and exceptional efficiency. Intuitive operation, programming capabilities and user-friendly features allows the SCOUT system to excel in a diverse field of applications. Set up times are reduced enormously, productivity is increased. The SCOUT system is fully compatible with most laser sources available in the industry. With the Scout synchronizing to various robots or PLC machine controllers is straightforward using common communication protocols.

Top benefits of the Scout system:

- Available for different power levels up to 5 kW (QBH)

- Delivers accuracies from ±2 to ±13 microns

- Working distances from 100 mm to 520 mm possible

- Field of views from 40 mm x 40 mm to 300 mm x 300 mm available

- Easy and intuitive setup and operation

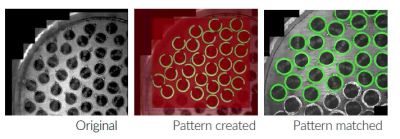

- Versatile recognition and image processing features

- Pre-programmed and custom geometries for easy welding patterns and designs

- Increased processing capability

- Faster production thanks to the repositioning function

- Robust and reliable

K-Draw® - intuitive, smart and flexible software:

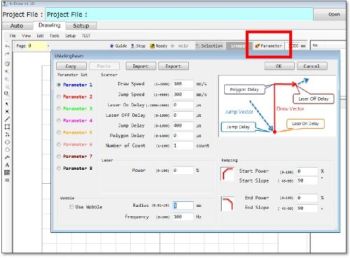

Even the best developed hardware remains useless without a smart control. One of the core technologies of the Scout system is the K-Draw® user software interface – a powerful and highly configurable software, which combines the scan head, the laser source together with a sophisticated vision system. After the first scan, the software enables a high-resolution view on the workpiece. Than the work field can be configured individually or with some pre-masks and the reference sections have to be set on the part. Now the unique repositioning function of the Scout is ready to find the piece wherever it is in the work area, targets it and performs a perfectly uniform application. This works great for smaller and precise parts, but also for larger and complex part geometries.

K-Draw® - intuitive, smart andflexible software

K-Draw® - intuitive, smart andflexible software

Application example

Applications:

Laser Welding, Laser Cutting, Additive Applications

Datasheet: K-Lab Scout Datasheet

More information on the set-up and possible applications can be found in the follwing application report.

Contact

Christian Schröter

This email address is being protected from spambots. You need JavaScript enabled to view it.

Mobile: +49-(0)160-96216120

Optoprim France

Optoprim France Optoprim Italy

Optoprim Italy